A 2021 Overview of the Plastic Injection Molding Market

By staying aware of changing trends and forecasted market changes, you can make informed decisions for your next plastic injection molding project.

Here are K&B’s top four takeaways for the plastic injection molding market.

High Demand for Polypropylene (PP) Injection Molded Plastics

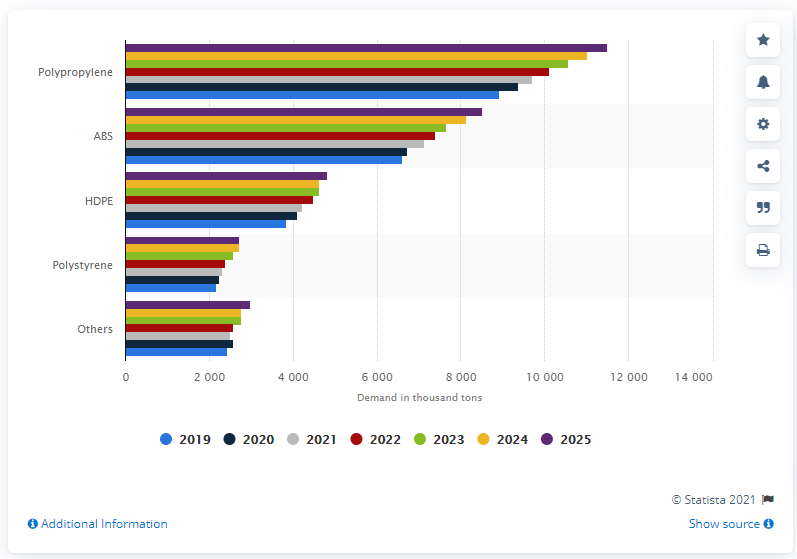

The graph below shows “the demand forecast for injection molded plastics in the United States from 2019 to 2025.”

The forecast reveals that “the U.S. demand for polypropylene (PP) injection molded plastics will amount to some 11.5 million tons in 2025.”

In 2024, the U.S. demand for PP injection molded plastics is expected to reach 11 million tons. In 2023, the demand is projected to be at 10.57 million tons.

ABS injection molded plastics will reach 8.5 million tons in U.S. demand

Acrylonitrile butadiene styrene or ABS injection molded plastics will have the second-highest U.S. demand until 2025, while HDPE injection molded plastics will have the third-highest demand.

ABS injection molded plastics will reach about 8.5 million tons in demand by 2025.

HDPE injection molded plastics will reach about 4.8 million tons in demand by 2025.

Sector Growth To Spur Demand

The growth of the healthcare sector is expected to propel the growth of the plastics injection molding market.

In addition, the “adoption of lightweight vehicles and electric vehicles” is also expected to provide different “lucrative opportunities for the growth of the market.”

Aside from that, “the growing demand for packaging for cosmetics and toiletries, pharmaceuticals, household chemicals, and food & beverages” is expected to increase “the demand of injection molded plastics.“

The growth of the plastics injection molding market is also expected to be propelled by the “increasing demand of molded plastics in electronic appliances such as laptops, cell phones, washing machines, and others.”

Medical Devices Embrace Injection Molded Plastics

The medical industry has been “replacing metal components and complete equipment with plastic injection molded products.” This increasing usage is “owing to properties such as biocompatibility and optical clarity.”

Some examples of medical devices that have a rising need for plastic injection molding include catheters, syringes, diagnostic equipment, implants, braces, and prosthetics.

It is expected that more medical devices will switch to plastic injection molding from metal use.

It is also projected that the increase will go “beyond the estimated growth rate of 6.5% over the next 10 years.“

The North American region, which includes the US, is observed to be “the largest market of plastic molding for medical devices.