MOLDED PRODUCTS FOR ANY INDUSTRY

Utilizing our many capabilities, including sonic welding, overmolding and hot stamping, we’ve molded components for a variety of applications.

Temperature-Setting Knob

K&B was recently approached by an appliance manufacturer that required a unique temperature-setting knob for use on commercial oven models.

Nozzle Adapter for Fuel Oil Heater

At K&B Molded Products, we manufactured the nozzle adapter highlighted here for use in a forced-air fuel oil heater.

Support Cross for Motor Mount

Modern manufacturers must keep pace through innovation and ingenuity.

Thermoplastic Rubber Adapter

with hose clamps and cap installed.

Polypropylene Base

Several styles of this product screw together with an Acrylic Bowl. When assembled with metal screen, they make a water filter for camping.

Carbon Filled Nylon Impeller

Base with a powdered metal insert over-molded in the hub. A matching top plate is ultrasonically welded onto this part in a secondary operation.

Two-Bladed Propeller

motor for a fishing trolling motor.

Two Piece Interlocking Collar

which when assembled, aligns a large paper roll on a steel shaft.

Two Piece Cradle

held together with one screw to stow a trolling motor when not in use.

Ventilation Hood

for exhaust gases from a hot water heater.

Instrument Panel

Rear view of the front cover for an instrument panel. This device is required to be water-tight.

7 Inch Acrylic Lens

for a road hazard warning signal.

Save time & Money On your products

Multi-Colored And Multi-Durometer

thermoplastic rubber handle grips for cushioning steel shafts.

Acetal Impellers

A 4 inch, submersible deep-well pump, showing the blade configuration prior to the top being ultrasonically welded onto the base.

polycarbonate housing

with polyester push buttons and curved arms assembled, which allow the screen angle to be adjusted.

Three Blade Propeller

for fishing trolling motor.

Peek Flanged Sleeve

with three brass threaded inserts molded into the part.

Acetal Bearing Retainer

formed by over molding 8 high-chrome steel balls. The acetal extends below the centerline to hold the balls in place and the lubricity of the material allows the balls to rotate in this low speed application.

Glass Filled Nylon

Locking Collar to locate a unit on a steel shaft.

ABS Adjustment Knob

with rotationally hot stamped numbering.

ABS Housing

with numerous compartments to hold various different components of the final assembly.

Glass/Mineral

filled Polypropylene Housing with four threaded studs over-molded into the part to allow a motor to be assembled.

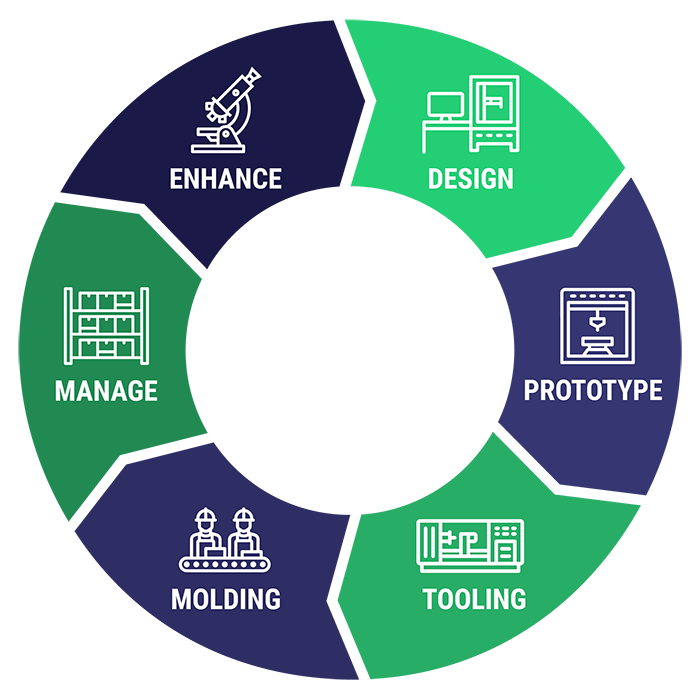

Our

Process

K&B has a proven 6-stage process that provides full-service solutions. We help companies navigate plastic injection molding methods to streamline products and processes, save money and work smarter. We don't just manufacturer the right parts, we evaluate the full process, helping companies deliver and outperform the competition.