Expert Molding Tool & Die

For more than half a century at K&B Molded Products, our expert tool and die design and manufacturing services have been an industry leading source for high-quality tooling and fixtures for discerning clients in a diverse range of industries. Our master tool and die professionals utilize advanced engineering software to create 3D renderings and in-process simulations, which allows us to validate the final design prior to manufacture.

We use a highly disciplined process to address all issues early in the product lifecycle. By fine-tuning mold, die, and fixture designs, we ensure that your products will be in compliance with all of your standards and requirements.

The well-honed skills of our technically educated tool makers allow them to expertly craft injection molds, die casting dies, as well as checking, assembly, hot stamping, and machining fixtures. We choose material of construction based on estimated lifecycle — from prototype tooling to fulfill early part requirements to robust, high integrity tooling for mass production.

Our stringent inspection processes are conducted by trained quality engineers in accordance with our ISO 9001:2008 quality management program. They incorporate dimensional inspection as well as feasibility testing and in-house tooling verification to ensure accurate and repeatable production of your parts.

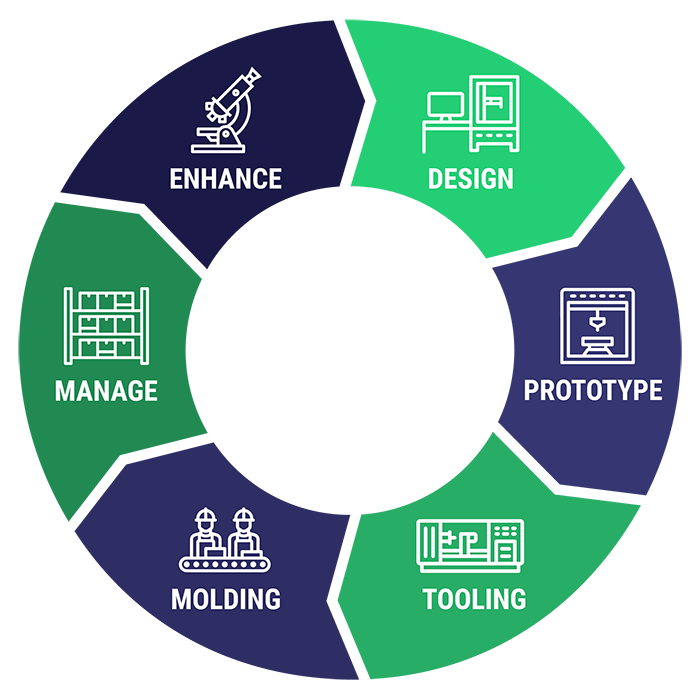

Our

Process

K&B has a proven 6-stage process that provides full-service solutions. We help companies navigate plastic injection molding methods to streamline products and processes, save money and work smarter. We don't just manufacturer the right parts, we evaluate the full process, helping companies deliver and outperform the competition.

We cost-effectively offer:

Save time & Money On your products

Regular maintenance ensures molds and dies are production-ready on a moment’s notice. We maintain comprehensive tool history documentation and are available to provide technical support on an ongoing basis for the lifetime of your tooling. In addition to our in-house resources, we also have access to overseas sources to provide cost-effective and efficient mold making solutions for projects with longer lead times or tight budgetary constraints.

For more information about our tool and die design capabilities, see the table below. Contact us at any time to discuss your project.

Molds & Tooling Specifications Table

| General Capabilities | Design Engineering Inspection Testing Tool History Documentation Technical Support |

| Die Types | Injection Molds Die Casting Dies |

| Tooling | Checking Fixtures Assembly Fixtures Hot Stamping Fixtures Machining Fixtures |

| Material Applications | Injection Molds

Die Cast Molds

|

| Typical Lead Times Available | 4 – 20 Weeks Depending on Mold Configuration |

Additional Information

| Industry Focus | Injection Molding Die Casting |

| Industry Standards | ISO 9001:2008 ISO 9001:2000 UL Registered |

| File Formats | DWG, DWZ AutoCAD DXF Drawing Interchange Format, or Drawing Exchange Format GIF Graphics Interchange Format IGES Initial Graphics Exchange Specification, ANSI file format. IDW, IPT Inventor JPG or JPEG Joint Photographic Experts Group Portable Document Format SLDPRT, SLDDRW, SLDDRT SolidWorks STEP Standard for the Exchange of Product Model Data |