Explaining Melt & Mold Temperature in Plastic Molding

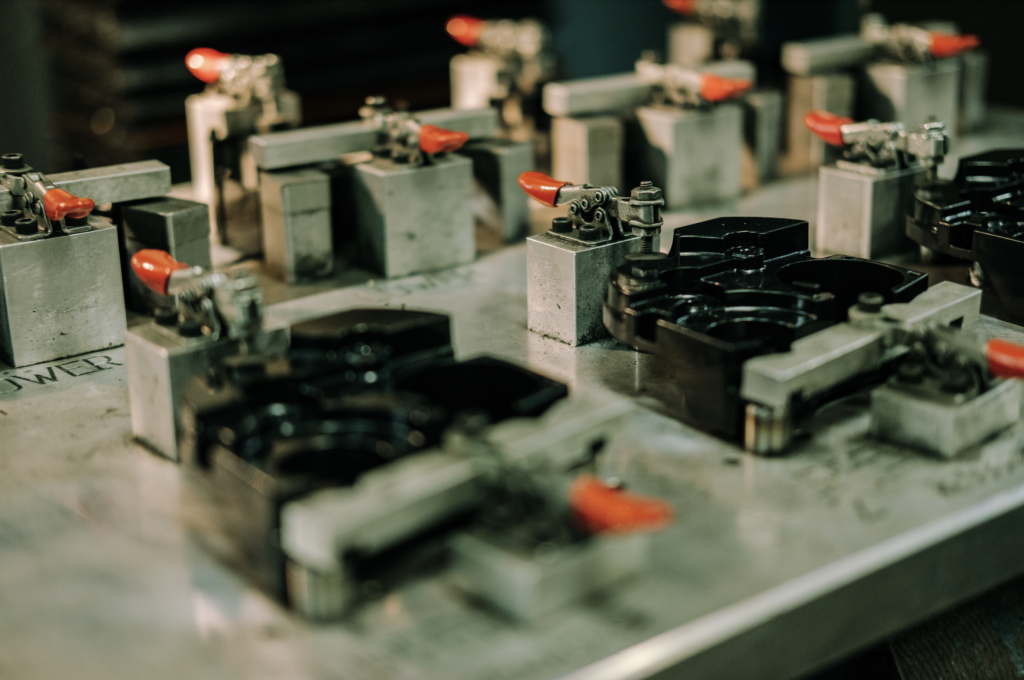

This is a story of the collaboration between two critical components for success in plastic injection molding. Proper melt temperature and mold temperature are paramount for ensuring your part’s final properties meet the requirements for its desired performance.

This post will give a brief explanation of the various aspects of melt temperature and mold temperature. Most importantly, understanding how the two work together during the plastic molding process is essential in order to produce a higher quality part at a lower cost.

Explaining Melt Temperature

Reviewing the melt temperature must be occur periodically throught the molding process; this is not area to set it and forget it. As resin changes during the devlopment process, the temparture will change as the resin propreties evolve.

Depending on the type of resin used, melt temperature can have varying effects on the resin’s properties, such as:

- Resin viscosity and texture

- Resin’s final weight in the finished product due to molecular changes

When determining the ideal melt temperature, take these into consideration:

- Chosen resin

- Screw and barrel design

- Further mechanical work on the product

- Final product requirements according to performance desired

- Melt temperature issues

- Inconsistent and non-homogenous melt temperature

Explaining Mold Temperature

In plastic molding, improper mold temperature can result in defects, such as mold warpage, sink marks and jetting. Depending on the type of resin used, mold temperature can impact properties, such as:

- Molded-in stress

- Fatigue, wear and creep resistance

- Final molecular weight

- Dimensional Stability

- Mold Temperature Issues

- Mold Temperature is Inconsistent

- Mold Temperature Non-Uniform to Part Cavity Proximity

Considerations with Plastic Molding Temperature

To successfully manufacture parts, a molder must take both into consideration. Oftentimes, a lower melt temperature combined with a higher mold temperature will achieve the optimal performance measures.

However, many button-pushing plastic injection molders do not have the technical expertise to implement and monitor these two critical aspects of plastic molding. Instead they see high melt temperature as the only solution for reducing resin viscosity.

Higher melt temperature will result in unsatisfactory and, in the worst cases, unusable products. Beyond a low-grade product, higher melt temperatures can have unwanted effects such as:

- Resin degradation

- Longer than average cooling cycles

- Increased energy consumption that could be avoided

Now, these plastic molders are forced to reduce the mold temperature in order to regain the lost productivity caused by long cooling cycles necessitated by higher melt temperatures. This high melt temperature to low mold temperature ratio often results in compromised part properties and an unstable part.

Instead, if they combined a lower melt temperature with a higher mold temperature they would likely create a part with better final properties and shorter cycle time, which would improve part quality and reduce costs.

Plastic Molding with K&B

For more than 50 years, K&B Molded Products has been delivering the high quality, cost-effective benefits of injection molding to industries like HVAC, Marine, Wastewater Management, and other markets across the country. We’re proud to stand by stringent standards for quality and fast turnaround times, as well as contributing professional experience and respect to both in-house and custom design work.

For more information about the benefits of reshoring, as well as answers to frequently asked questions about plastic injection molding, download our latest eBook, “10 Things to Ask Your Plastic Injection Molder.”