Commercial vs. Fine Molding Tolerances: Do You Know What You Need for Your Project’s Material?

Every plastic is different. Derived from different source materials with different synthetization methods, the properties and costs of plastics vary widely.

One of these properties, however, is sometimes overlooked in the plastic injection molding process: the tolerances that given plastics can hold. Knowing the tolerance requirements for your project’s material plays a major factor in its ultimate production cost.

Commercial vs. Fine Tolerances

In a production environment, manufacturers and fabricators generally offer two different types of tolerances: commercial tolerance and fine tolerances. Commercial tolerance is the widest tolerance a mold can hold. As you might guess, the ultimate benefit of a less strict tolerance is lower costs. Fine tolerance is the tightest tolerance that can be held, generally requiring more advanced production processes carrying higher costs.

Plastic Injection Molding Tolerances

In the world of plastics manufacturing, tolerances are determined by both production process and the type of plastic being used. This is particularly true for injection molding tolerances; plastic injection molding is commonly used to create parts with complex geometries that involve many different measurements and, therefore, many different tolerances that must be held.

It is important to understand the tolerance holding properties of the most common plastics used in injection molding, considering the numerous variables that determine molding tolerances for injection molding with plastic. These materials include:

- Acrylonitrile Butadiene Styrene (ABS)

- Polyamides, including Nylon

- Polyoxymethylenes, including Acetal

- Polycarbonates

- Polypropylene

- Thermoplastic polyesters

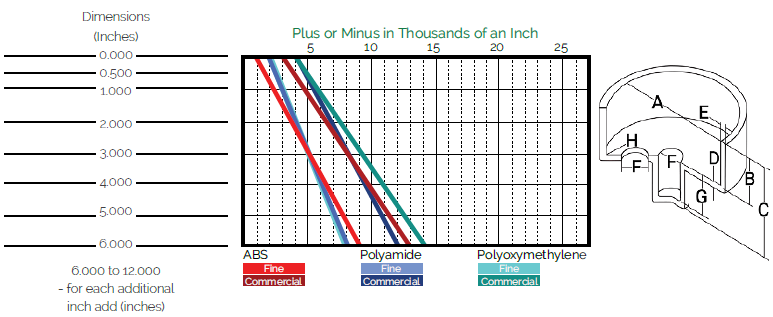

An Example of Molding Tolerances

To help illustrate how plastic properties affect part tolerances, consider a relatively simple injection molded part made from ABS.

If the part has a diameter of 2”, ABS will allow for a commercial tolerance of 0.007” and a fine tolerance of 0.004”. If the part’s diameter is increased to 6”, its tolerances increase accordingly. Commercial tolerance would increase by nearly double to 0.013” and fine tolerances will double to 0.008”.

Manufacturers like K&B can also use machining capabilities to meet extremely tight tolerances when necessary.

K&B Can Help

With more than 50 years of injection molding experience, K&B Molded Products has an in-depth knowledge of a wide range of plastics and their properties, including their ability to hold tolerances.

In order to help you design your next project effectively, we’ve compiled a chart detailing the varying tolerances of six of the most common injection molding plastics. When designing your next injection molded part, you can consult the chart as a quick reference, helping you to determine if you need the tolerances you’ve specified, and if you can afford them.