Nozzle Adapter for

Fuel Oil Heater

As leaders in the field of metal-to-plastic conversions, we are continually identifying opportunities to assist our customers with improving the performance while reducing the cost of components currently produced in metal.

THE

PROBLEM

At K&B Molded Products, we manufactured the nozzle adapter highlighted here for use in a forced-air fuel oil heater.

While on a site visit to an existing client facility, we noticed an aluminum assembly on their factory floor that was an ideal candidate for conversion.

Machined and then drilled and tapped to accept two brass barbed ferrules, we ascertained that we could mold the part at a significantly reduced cost while also eliminating the need for the secondary threading operations.

This project presented several challenges. Prototyping revealed that when injection molded, the thick walls of the 1.0” hex shaped body left sinks, which led to difficulty holding the close internal tolerances.

Our

Process

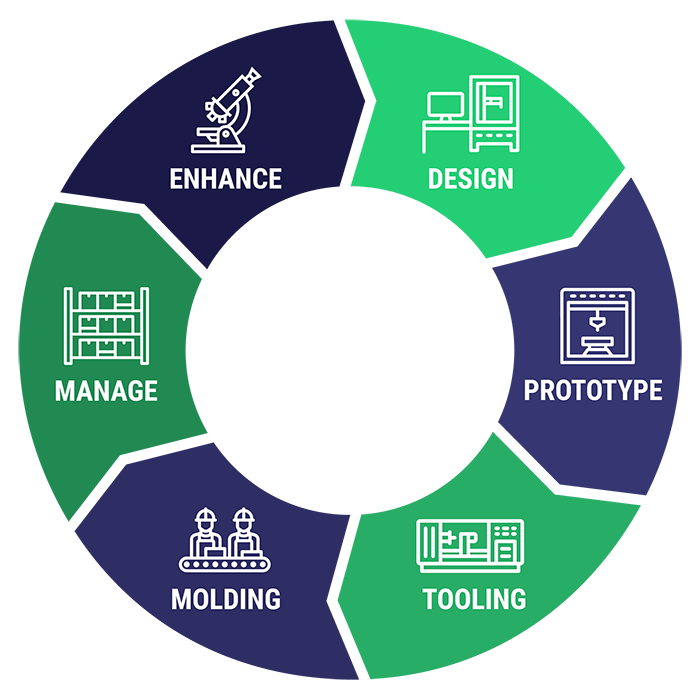

K&B has a proven 6-stage process that provides full-service solutions. We help companies navigate plastic injection molding methods to streamline products and processes, save money and work smarter. We don't just manufacturer the right parts, we evaluate the full process, helping companies deliver and outperform the competition.

THE

SOLUTION

Our engineers resolved the issue by reducing the hex dimension to ¾”, which allowed us to achieve precise dimensional accuracy without interfering with part functionality.

The challenge to our tool makers was to form the internal threads in the main body and core the small side holes for the hose barb ferrules, all while keeping the holes open and free of flash.

After finalizing part geometry, material selection, and tooling, we injection molded the parts using glass-reinforced, high heat nylon 6/6.

The final part featured overall dimensions of 1.312” in length x 1.375” in width x .875” in height, and we upheld very close ±.002” tolerances.

The client was very impressed with the results, and especially pleased with the 90% reduction in cost when compared to the original machined aluminum version. Current production continues at the rate of 5,000 to 125,000 units per year.

SPECIFICATIONS TABLE

| Project Name & Description | Chamber in which fuel oil and air are mixed for combustion |

| Capabilities Applied/Processes | Primary: Injection Molding Secondary: Power Hand Tools to remove mold details after part is solid |

| Equipment Used to Manufacture Part | 70 TON shuttle Type Injection Molding Machine |

| Overall Part Dimensions | 1.312” x 1.375” x .875” |

| Tightest Tolerances | ±.002” |

| Material Used | 6/6 Nylon-High Heat –Glass Reinforced |

| Industry for Use | Forced Air Fuel Oil Heater |

| Volume | As few at 5,000/year As many as 125,000/year |

| Delivery/Turnaround Time | 3 to 4 weeks |

| Delivery Location | Kentucky Indiana Italy |

| Standards Met | Customer Supplied Print |

Save time & Money On your products

Resources

10 THINGS TO ASK YOUR MOLDER

There are a number of things manufacturers must consider before selecting the proper plastic injection molder...

Download

MOLDING TOLERANCES CHART

Since tolerances ultimately impact your mold’s capabilities and production cost, K&B has developed a Molding Tolerances...

Download

PLASTIC INJECTION MOLDING GLOSSARY

Parameters and timing are critical factors in the injection molding process. Partnering with an experienced...