Plastic Injection Molding, Custom Molds & Tolling

Turnkey

Solutions for Plastic Injection Molded Products

Our

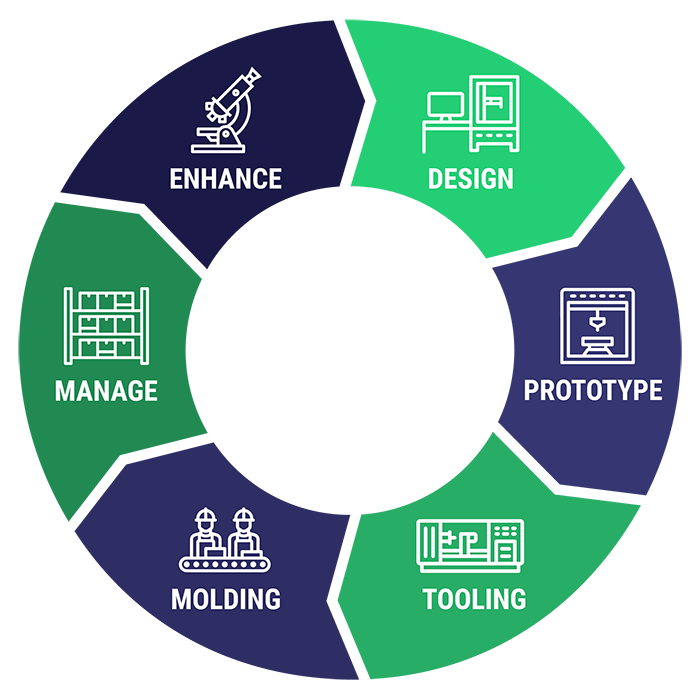

Process

K&B has a proven 6-stage process that provides full-service solutions. We help companies navigate plastic injection molding methods to streamline products and processes, save money and work smarter. We don't just manufacturer the right parts, we evaluate the full process, helping companies deliver and outperform the competition.

“K&B has been our supplier for over 30 years. They go above and beyond what is needed to ensure that we get the best quality and on-time deliveries. K&B has been instrumental in helping us achieve our goals.”

Purchasing Manager

Fortune 1000 Company

Save time & Money On your products

Our Work

THERMOPLASTIC RUBBER ADAPTER

with hose clamps and cap installed.

Utilizing our many capabilities, including sonic welding, over-molding and hot stamping, we've molded components for a variety of applications.

CARBON FILLED NYLON IMPELLER

Base with a powdered metal insert over-molded in the hub. A matching top plate is ultrasonically welded onto this part in a secondary operation.

Utilizing our many capabilities, including sonic welding, over-molding and hot stamping, we've molded components for a variety of applications.

TWO PIECE INTERLOCKING COLLAR

which when assembled, aligns a large paper roll on a steel shaft.

Utilizing our many capabilities, including sonic welding, over-molding and hot stamping, we've molded components for a variety of applications.

Resources

10 THINGS TO ASK YOUR MOLDER

There are a number of things manufacturers must consider before selecting the proper plastic injection molder...

Download

MOLDING TOLERANCES CHART

Since tolerances ultimately impact your mold’s capabilities and production cost, K&B has developed a Molding Tolerances...

Download

PLASTIC INJECTION MOLDING GLOSSARY

Parameters and timing are critical factors in the injection molding process. Partnering with an experienced...